Gotilo Inspect

For a flawless manufacturing process

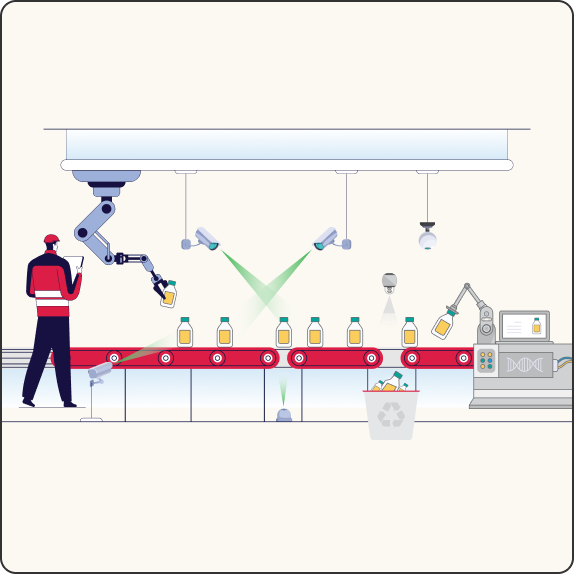

Gotilo Line is an AI-powered visual inspection solution designed to enhance quality control in manufacturing. for production lines. It automates the process of measurement and defect detection for identifying anomalies and improving precision.

Gotilo Inspect helps manufacturers tackle their quality-related challenges through advanced AI visual inspection. It makes it easy to meet product quality standards across production.

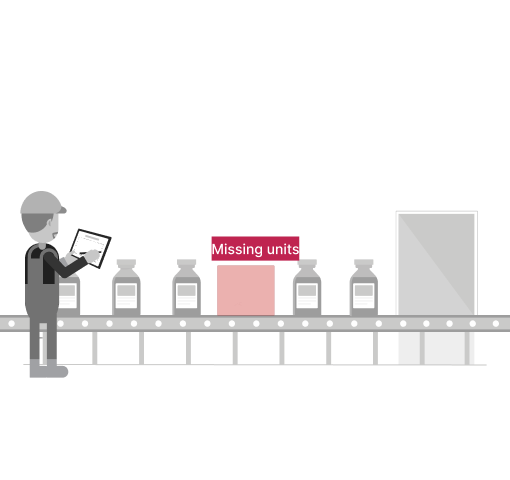

Manual inspection processes are human dependent and can lead to failure in catching subtle defects.

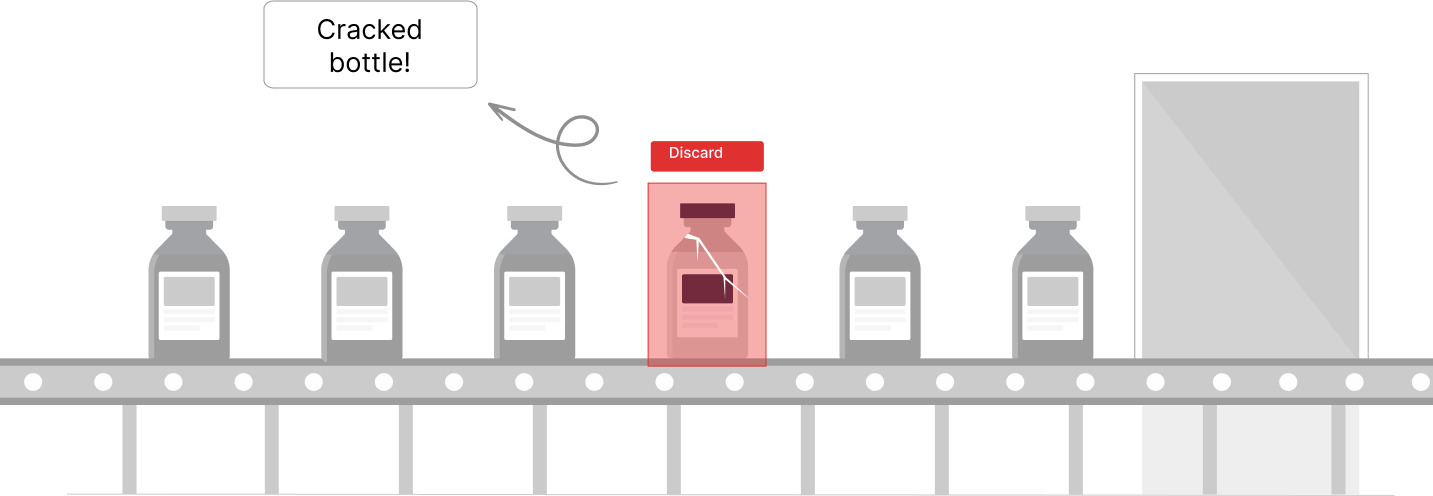

Golito Inspect can automatically detect defects in real time so that no anomaly goes unnoticed.

Since traditional inspection relies on humans, there can be inconsistency in measurement, leading to inconsistency in quality control.

Gotilo Inspect facilitates accurate, non-contact measurement inspections with consistent results and high precision.

Traditional inspection methods are slow and prone to inefficiencies and can delay production timelines.

With Gotilo Inspect, you don’t have to put in extra efforts or resources as inspection automation operates 24/7, without external intervention.

If quality checks are inadequate, it leads to high waste and increased costs.

Gotilo Inspect minimizes errors and quality issues, resulting in reduced material waste.

Physical contact during inspection is not the best option for some products.

Gotilo Inspect uses advanced AI visual inspection techniques that are non-invasive due to zero contact with the products.

It can identify surface defects, scratches and any other anomalies instantly, with great precision.

Operates continuously and provides real-time insights into the quality of production line output.

Conducts accurate measurement and ensures every product meets the set criteria for quality standard.

Provides detailed reports on defects and measurements for informed decision-making when needed.

Helps maintaining product integrity by using advanced AI tech for inspection which doesn’t require physical interference.

Detects holes, frayed threads and uneven textures to ensure fabric quality.

Identifies damages such as tears or misaligned seals, for food packaging inspection to maintain product integrity.

Monitors for cracks, contamination, or defects in packaging and compliance with safety standards.

Inspects for surface imperfections, cracks and incomplete molding in plastic products.

Detects cracks, dents and structural flaws in metal components for best quality output.

Identifies splits, holes and similar defects on the surfaces to ensure high-quality products.

You’ll like Gotilo if you care about efficiency, throughput, workplace safety, detecting dangerous conditions and space utilization. Contact us today for a free consultation.

Book a free demo